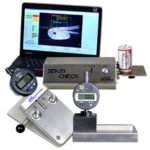

Seaming quality is critical and important for can inspection. And it’s the one of the most concerned point for can, beverage and food manufacturing companies. AT2E SeamCheck Automatic Double Seam Projector provides the most convenient way to accomplish the seam inspection.

Using with AT2E seam saw, a clear seam section image could be obtained. Along with professional SeamCheck software, a fast and accurate seam measurement could be done.

Characteristics:

- Automatic line positioning (auto-measure function), measurement will be done in 1 second

- Equipped with advanced video capture device which interference-free of external light source and ensured the high image definition

- Software adopted database management system, measuring results and images can be saved in the database and users can review the saved data at any time

- 9 measuring parameters: Seam Length, Body Hook Length, End Hook Length, Overlap, Seam gap, Overlap rate, Body Hook lapping rate, End Hook lapping rate, On-screen Seam Thickness. (Able to extend to 12 parameters through extra gauges, included actual Seam Thickness, actual countersink and Tightness)

- SPC compatible, use a data adapter to collect the data from Mitutoyo Digital Indicator (Actual Seam Thickness; Actual countersink; Actual can height, Actual flange width)

- Data can be exported as an Excel file

- Report format can be customized, flexible for different report styles of different companies

- Predefine various qualification standards, auto judge and warn whether the results are qualified in every measure

- Measurement results and label lines mark directly on the image, results will also display in corresponding field on the screen

- Graph chart statistic function, automatically analyze and compare the measurement results

- Magnifier option enable users to magnify the testing image for a more accurate line positioning

- Measured values are displayed in on-screen and alarm if values are not within specs

- Seam image can be printed and stored

- Provided with calibration piece, calibrate at any time

- Platform adjustable

- Light adjustable

Equipment includes:

- SeamCheck video seam projector

- SeamCheck professional seam measurement software

- 2 mm calibration piece

- Power supply: 115 V/230V

- Serial interface: RS 232 C

- Resolution: 0,001mm

- Accuracy: 0,005 mm

- Magnification factor: 60 X

- Line positioning magnification factor: 180 X

- Platform capacity: Up to 180 mm dia. can

- Dimension : 470 (L) x 200 (W) x 125 (H) mm

- Net weight: 5 kg

- ANSS – Antinoise Seaming Cutting Saw / SS-1 Seaming Cutting Saw

- STG-1 Seam Thickness Gauge (digital)

- CG-D Countersink Gauge (digital)

- FWG-1 Flange Width Gauge

- HG-1 Height Gauge

- DTB-1 Data transporting Box with cables