PLS – Production Line simulator

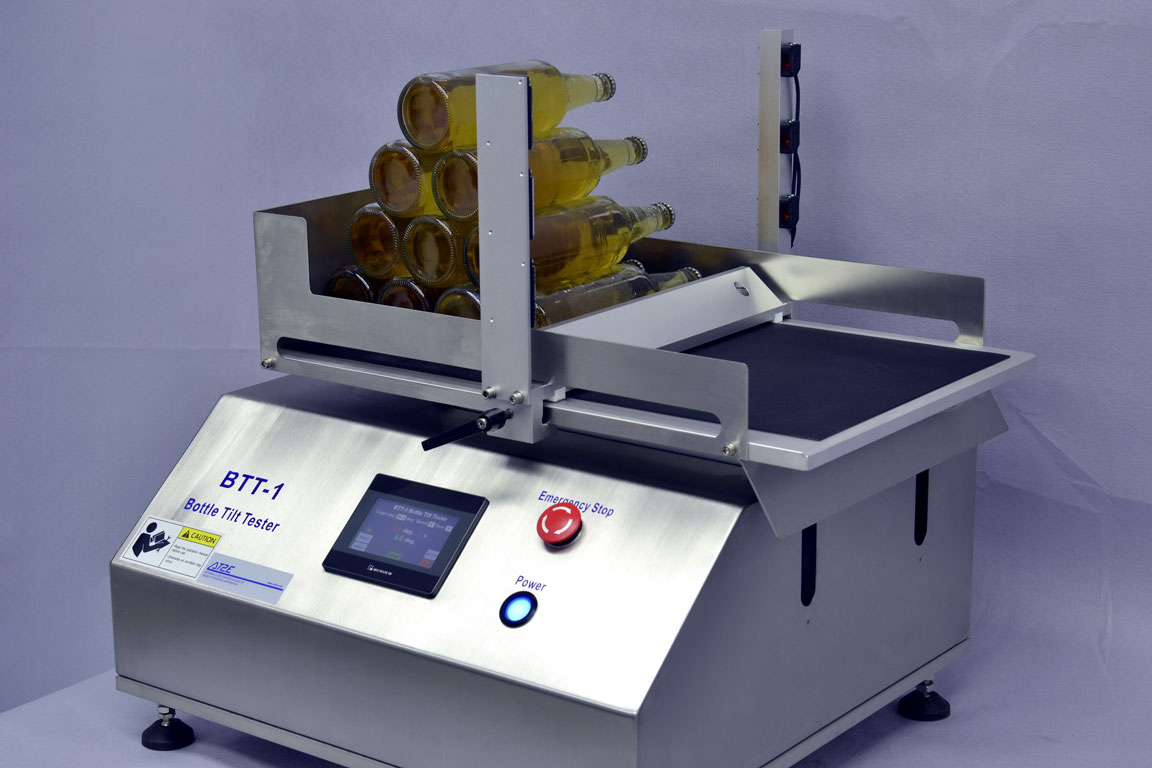

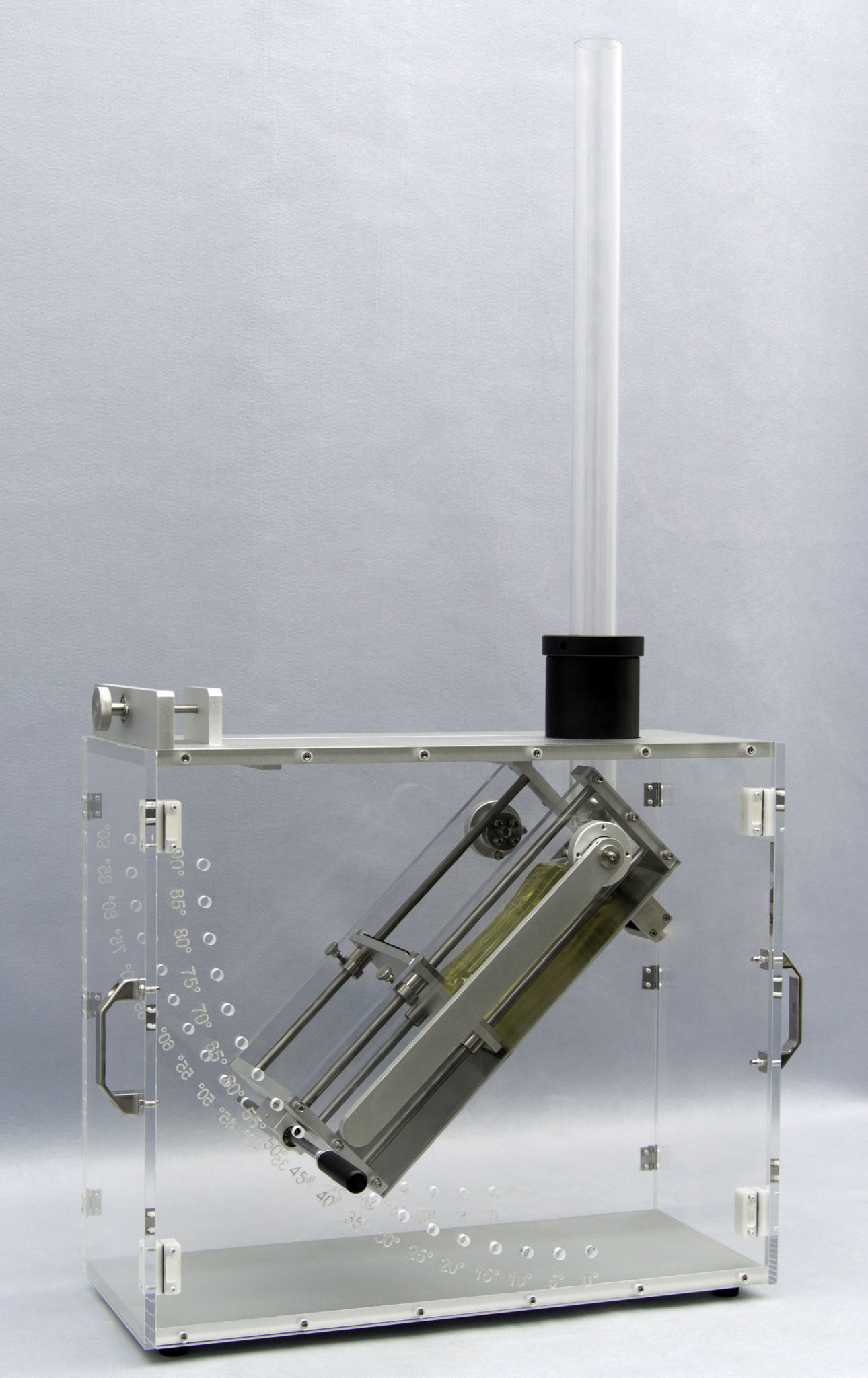

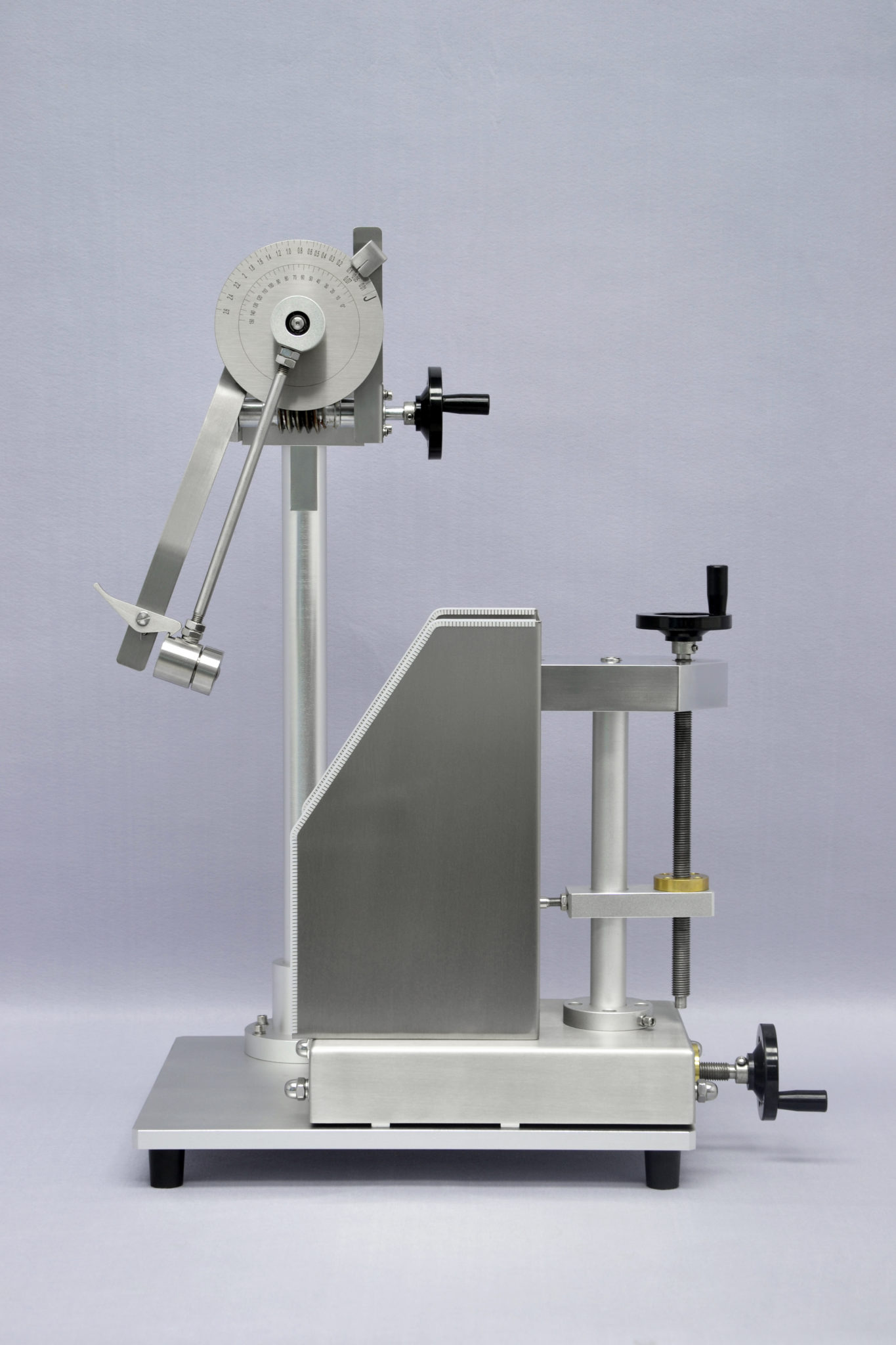

DescriptionPhotosDescription The PLS Production Line Simulator allows to simulate in a reproducible and accelerated way the friction on a packaging line. The testing process simulates the abrasions associated with contacts between bottles, typical of packaging lines. It is the ideal device for determining the build quality of glass bottles as well as their coatings, decorations…